SEARCH BLOGS

BLOG TOPICS

BLOG ARTICLES

-

Old clinserts part numbers

Fri Apr 2025

-

Where in the MRO market are broaching tools used?

Wed Mar 2025

-

Airplane engine CF34-10E

Fri Feb 2025

-

What tools are used to repair a PW123E Engine?

Fri Feb 2025

-

Do you have the coated spare blades 217-074801 or...

Thu Feb 2025

on 22 Jan 2021 2:03 PM

0 comments

This is a set of questions and answers.

First of all, keenserts are military grade products and are also used into the aerospace market.

We would recommend to use Clinserts.

Let me answer to your questions by first explaining that the Insert needs to first be installed by threading it in and slamming the Clins into the parent material, so that it will not rotate when you manipulate the bolt.

1. When tapping the hole to insert the Clinserts, what is the best method to make sure the thread is “straight”?

Answer:

I do think that it is important to purchase a good tap: either hand or machine tap. Dependent on the hole: (straight through or blind hole) you will use a different tap. Please consider that the Inserts are made with an outside thread tolerance 6h, which means you need to make sure that your thread is tapped to the same or higher quality. However, with a standard tap this is already accomplished.

https://clinserts.com/which-thread-tolerance-are-clinserts-made

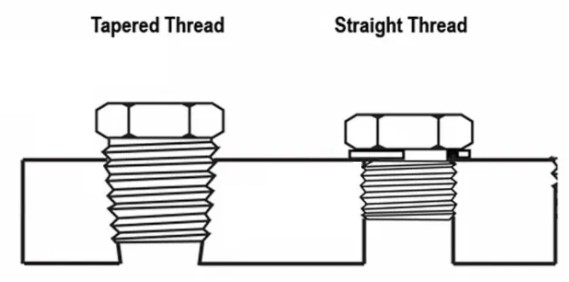

regarding the difference between straight and tapered thread, see below picture. It means that with a blind hole, you need a special tap, as the first threads that are cut will be cut straighter. With a blind hole, you have the advantage you can move the tap deeper, making the thread straight.

Off course make sure that your hole is drilled to the correct diameter to start off, before cutting the thread.

2. Is it possible to install the Clinserts manually, what is the torque value to be applied?

Answer:

Clinserts are mostly installed with a manual tool. First you need to

https://clinserts.com/products/installation-instructions

as a further recommendation, it is recommended to use a countersunk tool, once you feel the Clinsert is flush to the surface, please do an extra quarter turn, so it sits slightly below the surface of the panel.

Then you can hammer the Clins into the mother material with help of the tool.

- I visited the link. STEP3 is about Clinserts Installation. The question is: is it possible to install it without any specifc tool? if no tool is used is it sufficient to snugh tight them without any specifc torque value?

Answer:

With snug tight you mean that you is that you can screw them in just by hand and do not require a tool to untight them. Well, yes, you can do it this way. The Insert will be stopped by Clins being pushed against the mother material. So in case your countersunk is to deep, your insert will then install to deep.

3. When inserting the Clinserts manually, is it recommended/forbidden to put additional adhesive such as Loctite?

Answer:

You can do this, however it is not needed, as the Clins will block the rotation.

4. When tightening the bolt into the Clinserts, is it always possible to reach the maximum torque given by the std. for the specific bolt size?

Answer:

Yes, Clinserts are specifically used to guarantee that your thread will not wear off, due to overtightening. Off course, since they are made in hardened stainless steel, and you decide to use a bolt made in a material that is very hard, it might you manipulate too much and the Thread starts to deform. For these exceptional cases, we have stated the shear engagement per mm² so you can calculate yourself to which tightening torque the bolt should be manipulated.

- Most commonly we use carbon steel bolt 8.8 galvanized. This is our torque table. Can you confirm this torque value can be applied to clinserts?

Answer:

Yes you can, since you use standard bolts, however we always state that the customer is responsible for the use of our products in his own application. So I cannot grant any warranty on mis-use, overtightening, …

5. When tightening the bolt into the Clinsert, is it recommended/forbidden to put additional adhesive such as Loctite?

Answer:

On the contrary, we recommend to use a lubricant when you would use stainless steel bolts, reason is to avoid gripping of the material, in case you want to later untighten it again. But if you have no intention to unscrew the bolt later on, they you can put additional adhesive.

- For stainless steel I agree with the use of oil. But what about carbon stell 8.8: would the application of Loctite be a problem? Especially by opening and closing the bolt several time, is there the risk the clinserts gets loosen?

Answer:

If you apply Loctite, you will have the issue that when you manipulate the bolt with too much force, you probably will damage the external thread of the bolt and internal thread of the insert, since the diameter of these threads is smaller then the external thread diameter of the Insert. So yes, you might have issues. I do not see the Clinsert loosening though, as the Clins will block the rotation. Unless again, you have drilled your hole not according to the required specification. In the end, best is to test it in your own application.

6. When removing a bolt from Clinserts what does prevent the Clinsert from being also untightened?

Answer:

the Clins.

- Clear, but the clins could gain “play” in the parent material (especially when this is soft like aluminium) or am I worng?

Answer:

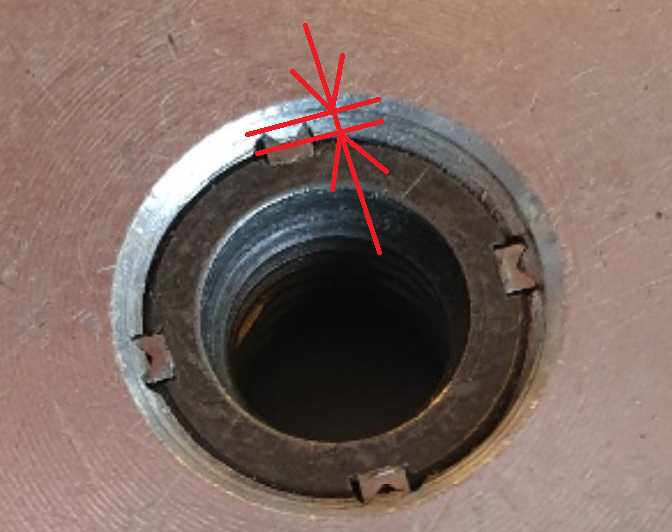

Here you see a Clinsert installed in Aluminimum

You see clearly that parent material has been moved and that the Clins penetrated into this, creating a diameter of material that needs to be pushed away when you manipulate the bolt too much.

I do think if you hit hard enough on anything it will break eventually.

However if you talk about the strongest Insert in the world, the Clinsert is the best option you have.

I would recommend, if you are really concerned to use heavy duty inserts, there the outside diameter is even bigger, which will create less concerns for you.

https://clinserts.com/products/clh-series

other options is to use A286 which is an aerospace grade material

Don’t hesitate to contact us back for a quote or further technical advice.

For attractions, and in case you require a nut that does not come loose due to vibration, please consider using Auto-Lok Nuts

https://anemo.eu/locking-nuts/auto-lok-nut

Thanks,

Clinsert Team