SEARCH BLOGS

BLOG TOPICS

BLOG ARTICLES

-

Old clinserts part numbers

Fri Apr 2025

-

Where in the MRO market are broaching tools used?

Wed Mar 2025

-

Airplane engine CF34-10E

Fri Feb 2025

-

What tools are used to repair a PW123E Engine?

Fri Feb 2025

-

Do you have the coated spare blades 217-074801 or...

Thu Feb 2025

on 26 Nov 2021 3:57 PM

0 comments

Question

I am validating a repair using a Clinsert CLHM20x2.5 thread insert. The original application is an M20x2.5 bolt into a steel casting of minimum yield strength 300MPa. The thread engagement is 21mm, torque 339Nm and there have been no problems with this arrangement over many years.

Because the insert is installed slightly below the joint surface thread engagement into the insert will be approx 20mm. I want to check that this thread engagement will be sufficient. The Clinsert catalogue says that the material of the inserts is stainless steel 1.4305 but standards give a minimum yield strength of 190MPa, much lower than my casting. However I am not confident that this is the applicable value specifically for the Clinsert insert. Please could you advise what yield and ultimate strength values I should use for the Insert in my calculations.

So what I am looking for is either:

- the correct yield strength of the material used for the Clinsert (preferred so I can do my own calculation)

- confirmation that the insert material is stronger than my original casting that has yield strength of 300Mpa

- Some data about the pull out strength of the M20 bolt in the M20 Keensert

Thank you very much.

Answer:

The material data is depending on the material lot. For the CLHM20x2.5 we currently have on stock (lot no. ###) we have a Rm of above 700 MPa and an Rp 0,2 above 500 MPa.

Take care the Clinserts will only be one part of the system and we do not have information about the screw and the parent material I cannot give a general answer.

We have a calculation equation for the Pull-out-strength that can be used, however, we need the value of your parent material

Calculation is as follows:

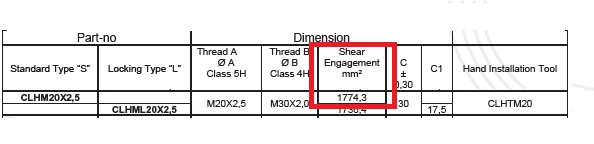

Pull-out-strength(N) = shear engagement (mm2) x ultimate shear strength of parent material (N/mm2) = 1774.3 x ? =

Shear engagement areas are shown on the data sheets