Error message

Notice: Undefined variable: isResisteelTool in include() (line 97 of /home/clinsertscom651519/domains/clinserts.com/public_html/sites/all/themes/jango/jango_sub/node--clinsert-tools.tpl.php).

Notice: Undefined variable: isResisteelBlade in include() (line 101 of /home/clinsertscom651519/domains/clinserts.com/public_html/sites/all/themes/jango/jango_sub/node--clinsert-tools.tpl.php).

Notice: Undefined variable: isblade in include() (line 145 of /home/clinsertscom651519/domains/clinserts.com/public_html/sites/all/themes/jango/jango_sub/node--clinsert-tools.tpl.php).

Notice: Undefined variable: isbt in include() (line 274 of /home/clinsertscom651519/domains/clinserts.com/public_html/sites/all/themes/jango/jango_sub/node--clinsert-tools.tpl.php).

SEARCH BLOGS

BLOG TOPICS

BLOG ARTICLES

-

Old clinserts part numbers

Fri Apr 2025

-

Where in the MRO market are broaching tools used?

Wed Mar 2025

-

Airplane engine CF34-10E

Fri Feb 2025

-

What tools are used to repair a PW123E Engine?

Fri Feb 2025

-

Do you have the coated spare blades 217-074801 or...

Thu Feb 2025

on 04 Mar 2021 9:54 AM

0 comments

Question:

My thread is made in cast aluminium. What happens is when they do it up they over tighten it then they start threading on an angle.

Please advise.

Answer:

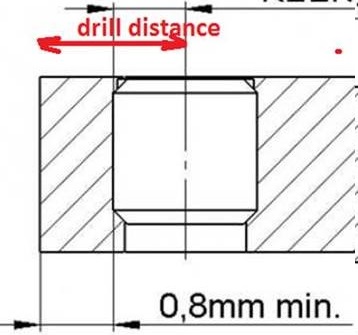

Clinserts are habitually installed at the side of a plate or close to the edge of a surface.

The risk exists, when installed to close that performance is influenced, and you do not achieve enough pull-out strengths.

1. Clinserts at the side of an edge

The general rule is to install with a drill distance of (0,8mm minimum + 1/2 diameter of the drilled hole)

advice to put all clins as far as possible from the edge.

Case 1: With CLM8, outside diameter = M12, drill distance can be 6,8mm.

Case 2: With CLM5, outside diameter = M8, drill distance can be 4,8mm.

Case 3: With CLHM20, outside diameter = M30, drill distance can be 15.8mm.

Tap marks may show on the flat side and the insert should be positioned with keys 45°to 90° (2 CLINS) offset from the flat side.

2. Clinsert in a boss

The general rule is to install the Clinsert in a boss with a minimum outside diameter = 1,5 x diameter of the outside thread of the Clinsert

Case 1: CLM8x1,25 with an outside diameter of M12 your boss diameter needs to be 18mm

Case 2: CLM5x0,8 with an outside diameter of M8 your boss diameter needs to be 12mm

Case 3: CLHM20x2,5 with an outside diameter of M30 your boss diameter needs to be 45mm